| ITEM | DESCRIPTION |

| GENERAL |

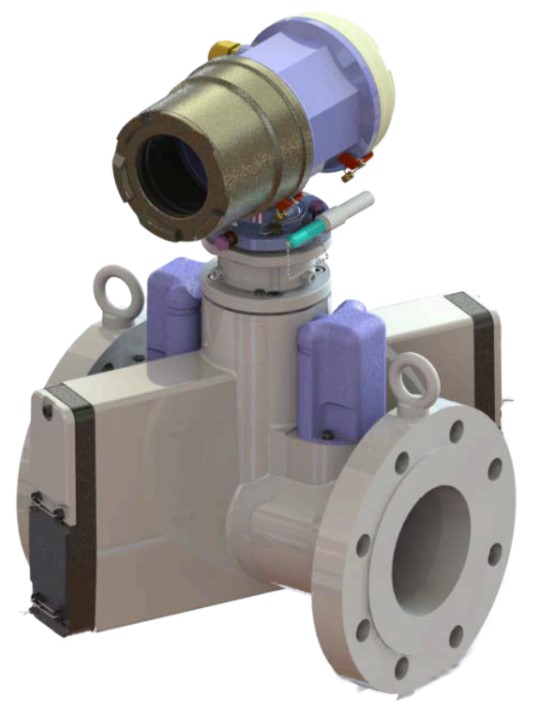

| Flow Meter Type | Four-Path Ultrasonic Gas Flow Meter with optional integral volume correction |

| Application | Flow measurement of Natural Gas (incl. custody transfer) |

| Flow Direction | Uni-Directional; bidirectional |

| Nominal diameters of Inline Section, mm | 80; 100; 150; 200;250; 300; 400; 500; 600 (Other sizes upon order) |

| Flange to flange size | 3 DN |

| PROCESS DATA |

| Process Fluid | Natural Gas |

| Flow range at operating conditions , m3/h | See Datasheet (rangeability 1 : 250) |

| Maximum Operating Pressure, MPa | 1.6; 2.5; 4.0; 6.3; 10; 16; 25 |

| Minimum flow speed, m/s | 0.1 |

| Ambient Temperature Range (°C) | min.:-25; max.: +55; min.:-25; max.: +70 |

| Pressure containment test | Hydraulic or Pneumatic test @ 1.5 x Maximum Operating Pressure |

| Ex protection marking as per EN ISO 60079-0:2012; EN ISO 60079-11:2012 | Ex II 2 (1) G Ex db ib [ia Ga] IIB T4 Gb |

| Ingress Protection | IP 67 |

| FLOW METER TECHNICAL FEATURES |

| Type | Ultrasonic Transit time |

| Accuracy | MPE equal to or better than ± 1.0% ( MID class 1 ) |

| USM Nominal Diameter, mm | As per line size |

| USM Flow rating | As per calibrated range |

| Process connections | Flanges PN (EN 1092); ANSI (ASME B 16.5) |

| Pressure and temperature measurement | Integral (optional) |

| USM Body Material | Aluminum(DN 80 … 150; Pressure 16 Barg) ; CS (all other sizes) |

| UM Mounting | Integral with Electronics Unit |

| Flow Straightener | Zanker type; NOT included in scope of supply |

| Straight pipe run | 10 DN Upstream and 3 DN downstream straight runs required – NOT included in scope of supply |

| TRANSDUCER (SENSOR) |

| Number of transducers/Channels | 4 pairs/ 4 channels |

| Transducer type | 200 KHz piezo-electric |

| Transducers Replaceable in Operation | Yes |

| Transducer Mounting | Inserted sensors |

| Transducer Housing Material | Stainless steel & special polymer lining |

| Transducer to EU Connection | Direct connection |

| Signal Outputs | 2 x LF / HF pulse outputs, 2 x NC 24 VDC 50 mA discrete outputs, 1 x RS 485 serial ports (Modbus RTU), 1x 4..20 mA current output; OR 2 x LF / HF pulse outputs, 2 x NC 24 VDC 50 mA discrete outputs, 2 x RS 485 serial ports (Modbus RTU) |

| Power Supply | (12+/-3) VDC external power supply ; optional integrated battery (autonomous operation life 5 years) |

| CERTIFICATES |

| Directive 2014/34/EU (ATEX) | ICQC24ATEX0511X |

| Directive 2014/68/EU (PED) | 24.93062/PED0205104 |

| Directive 2014/32/EU (MID) | SK 23-MI002-SMU006 |